From the development of the research to an initial test production of manufactured products and the definition of the production process of the new bioplastics derived from beer brewers: in recent months, the partners of LIFE RESTART, a project co-funded by the EU under the LIFE Programme, have deployed all their expertise to implement the planned activities and further tighten the links of a strategic collaboration that is one of the strengths of this innovative close-to-market project.

From the development of the research to an initial test production of manufactured products and the definition of the production process of the new bioplastics derived from beer brewers: in recent months, the partners of LIFE RESTART, a project co-funded by the EU under the LIFE Programme, have deployed all their expertise to implement the planned activities and further tighten the links of a strategic collaboration that is one of the strengths of this innovative close-to-market project.

Machinery and recipes

While tests continued on the formulations of the new biocomposites by the research group coordinated by Professor Annamaria Visco, Associate Professor in the Department of Engineering at the University of Messina, the machinery specially designed by UNIME for the Mechanical Treatment Prototype (MTP) for the processing of beer brewers’ brewing grains at the Messina Brewery, was purchased – and will soon be delivered – and can also be used for other agro-food wastes.

The plant will allow pilot-scale treatment of the spent grain, quality control of the treated waste, and further development of the tested formulations, among these, those recipes deemed most effective, together with crude prototype items, will be transferred to the Interdepartmental Research Centre ‘Biobased Reutilisation of Waste from Agro-Food Matrices (RIVIVE)’ at the University of Palermo. Here, under the supervision of Professor Nadka Tzankova Dintcheva of the Department of Engineering, the new bioplastics in pellet form will be produced in significant quantities, to assess the transferability of the production process on a larger scale.

In the meantime, some significant results of the research process were presented at the international workshop POLymers and Biopolymers for sustanaible LIFE organised by the Modification Degradation and Stabilisation Society held in early September in Sofia, Bulgaria.

Biodegradability and characterisation

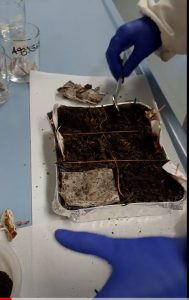

In turn, Crossing srl continued with the characterisation of the various formulations of bioplastic biocomposites and agricultural organic waste. In addition to dealing with biodegradability studies of the biopolymer samples extruded by UNIME, it is devoting itself to the complete characterisation of agricultural organic waste. Specifically, he is assessing the chemical-physical properties of the biomass, using Nuclear Magnetic Resonance (NMR) spectroscopic analysis, Infrared Spectroscopic Analysis (FT-IR) and Differential Scanning Calorimetry (DSC). It is also conducting extraction tests, in various solvents, of potential fine chemicals, while it will soon launch further studies on the biodegradability of biocomposites in the form of manufactured products, comparing them with the benchmarks of LIFE RESTART, which it presented at the 19th International Conference on Renewable Resources & Biorefineries in Riga, Latvia, at the end of May.

In turn, Crossing srl continued with the characterisation of the various formulations of bioplastic biocomposites and agricultural organic waste. In addition to dealing with biodegradability studies of the biopolymer samples extruded by UNIME, it is devoting itself to the complete characterisation of agricultural organic waste. Specifically, he is assessing the chemical-physical properties of the biomass, using Nuclear Magnetic Resonance (NMR) spectroscopic analysis, Infrared Spectroscopic Analysis (FT-IR) and Differential Scanning Calorimetry (DSC). It is also conducting extraction tests, in various solvents, of potential fine chemicals, while it will soon launch further studies on the biodegradability of biocomposites in the form of manufactured products, comparing them with the benchmarks of LIFE RESTART, which it presented at the 19th International Conference on Renewable Resources & Biorefineries in Riga, Latvia, at the end of May.

After carrying out an in-depth study on waste water from the Messina Brewery, Crossing srl is also carrying out activities for IP of the technology, with a constant update on the scientific and patent literature.

The first pilot production tests

UNIME, in synergy with Crossing srl, sent Bibetech S.p.A. a few kilograms of the very first bioplastics tested. In this way, the company was able to start a campaign of experimental tests in pilot batch productions to test the technical feasibility of industrialising these new materials, highlighting the criticalities and decisive levers on injection moulding technology. This know-how is also enhanced by its ability to design and develop projects, from mould creation to industrial testing in continuous production on complex or technical items. These initial batches of material show positive processing rates, such that very first samples of items can be produced.

Production Process, Social Business Plan, Market Analysis

Ecos-Med is the social cooperative responsible, among other things, for the management and development of the ‘Zero Factory’, the semi-industrial-scale production hub for bioplastics, which will be located in the former artisanal area of Roccavaldina, a small municipality in the Messina area. The cooperative has now finalised the final layout of the pilot plant, i.e. its location within the shed, and fine-tuned its production process.

Ecos-Med is the social cooperative responsible, among other things, for the management and development of the ‘Zero Factory’, the semi-industrial-scale production hub for bioplastics, which will be located in the former artisanal area of Roccavaldina, a small municipality in the Messina area. The cooperative has now finalised the final layout of the pilot plant, i.e. its location within the shed, and fine-tuned its production process.

The arrival of the machinery, which will treat the raw material and make the “pellets”, is scheduled for the end of the year, while production will start by early 2024. Meanwhile, the cooperative is preparing a Social Business Plan that will allow the employment of people in fragile conditions and aim to generate economic resources for the sustainable growth of the local community.

Upstream of the entire process, Birrificio Messina is proceeding with the identification of the plant for drying the spent grain and treating the residual water from beer production, while the project leader Fondazione Me.S.S.I.n.A. is also working to test the LIFE RESTART technology on further agrifood chains, in particular olive pomace and marc (from the oil and wine production process). It is also exploring the market to extend the range of potential manufactured products that can be produced with the new bioplastics.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor the granting authority can be held responsible for them.