Between Factory and “top recipes,” LIFE RESTART accelerates

Reuse of bEer SpenT

grAin

foR bioplasTics

We are now very close to “switching on” the Zero Factory in Roccavaldina. Soon the Energy Manager will finish the phase of analyzing the documents necessary to make the materially finished electrical connection operational. And then EcosMed will be able to start with a final test, this time on site, of the machinery-already thoroughly tested a first time at the producers’ premises-and the implementation of the first pilot pellets in situ, so as to develop samples to be screened by the distribution network and potential buyers. These are biomaterials whose formulations, the “recipes,” are largely ready and potentially marketable.

We are now very close to “switching on” the Zero Factory in Roccavaldina. Soon the Energy Manager will finish the phase of analyzing the documents necessary to make the materially finished electrical connection operational. And then EcosMed will be able to start with a final test, this time on site, of the machinery-already thoroughly tested a first time at the producers’ premises-and the implementation of the first pilot pellets in situ, so as to develop samples to be screened by the distribution network and potential buyers. These are biomaterials whose formulations, the “recipes,” are largely ready and potentially marketable.

Ad hoc testing and pots

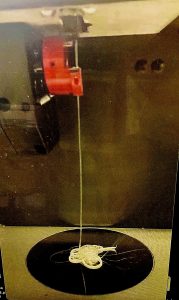

When fully operational, the Factory will reach semi-industrial scale production of the new bioplastics with the entirely green “recipes” developed, tested and analyzed by UNIME and Crossing. Initially, between 180 and 200 kilograms per hour will be produced and then production will be increased based on market demand, which in recent months has been variously sounded out with a view to future development of commercial agreements. In particular, a small quantity of the biomaterial has been tested in the sanitaryware and floriculture sectors, in which an important role will be played by Giardineria Italiana, a partner that has taken over from Bibetech, which will test pots made with these bioplastics, and with which the creation of an ad hoc pot, such as to make the most of its characteristics, is being evaluated.

As the start of production approaches, moreover, EcosMed has prepared and is about to publish a notice for the selection of three interns to be placed in the Zero Factory in Roccavaldina (ME). While on Sept. 18, in Athens, the cooperative participated, at the indication of Cooperazione Finanza Impresa (CFI), in the SIFTA Masterclass on Social Enterpreneurship for Microfinance and Social Finance Providers in Southern EU promoted by the European Investment Bank where it also presented the activities carried out under the LIFE RESTART project.

As the start of production approaches, moreover, EcosMed has prepared and is about to publish a notice for the selection of three interns to be placed in the Zero Factory in Roccavaldina (ME). While on Sept. 18, in Athens, the cooperative participated, at the indication of Cooperazione Finanza Impresa (CFI), in the SIFTA Masterclass on Social Enterpreneurship for Microfinance and Social Finance Providers in Southern EU promoted by the European Investment Bank where it also presented the activities carried out under the LIFE RESTART project.

The best formulations

On the research side, UNIME and Crossing, each in their own specifics, worked to identify the best operating conditions and consequently the best formulations for the production of biocomposites. Various blends of different biopolymers and agro-industrial wastes were studied, characterizing them from a physical, mechanical and chemical point of view. Specifically, different biopolymers from different suppliers and different agroindustrial wastes from different biomasses, including pomace, were analyzed. A variety of bio-based additives were also sourced to evaluate their effects in the final biocomposite.

UNIME also continued tests on the recyclability of biomaterials and refined the measurement of the fluidity index of biomaterials in relation to injection molding. While Crossing conducted studies of biodegradation in soil and composting of biocomposites at different formulations. Both indirect and direct biodegradation tests were conducted, following ASTM D5988.

UNIME also continued tests on the recyclability of biomaterials and refined the measurement of the fluidity index of biomaterials in relation to injection molding. While Crossing conducted studies of biodegradation in soil and composting of biocomposites at different formulations. Both indirect and direct biodegradation tests were conducted, following ASTM D5988.

Then, in recent months, the process related to bioplastics certifications has been going on, starting with the one for compostability. Fondazione Messina started the Life Circle Assesment, whose certification will be carried out by the University of Palermo, while tests of biomaterials oriented to obtain the one for toys are planned.

Finally, there were many dissemination events, national and international, in which the project partners participated.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor the granting authority can be held responsible for them.